Detailed introduction of rubber shock absorber

As a kind of important shock-absorbing components, rubber shock absorbers have been widely used in all kinds of machinery, automobiles, railway locomotives, water transport vehicles, aircraft and other devices. It can be said that rubber shock absorbers are required wherever shock absorption and isolation are required. The reason why rubber shock absorber is so widely used is that it effectively utilizes the following characteristics of rubber:

1. The shape of rubber can be freely selected, and the hardness can be adjusted through formula design to meet the requirements of stiffness and strength in different directions;

2. The stress-strain curve is an elliptical hysteresis line with an area equal to the vibration energy (damping) converted into heat in each vibration cycle, which can be adjusted through formula design;

3. Compared with steel, rubber has large elastic deformation and small elastic modulus;

4. Rubber has high elasticity and viscoelasticity;

5. The impact stiffness of rubber is greater than the dynamic stiffness, and the dynamic stiffness is greater than the static stiffness, which is conducive to reducing impact deformation and dynamic deformation;

6. Rubber is an incompressible material (Poisson’s ratio is 0.5)

According to different use conditions, rubber shock-absorbing devices can be designed into various types. At present, there are more than ten kinds of most commonly used:

1) YXn, xn rubber torsional vibration damper: used for automobile engine crankshaft system [1].

2) JV type cylindrical spring shock absorber: used for various instruments and meters.

3) 6jx shock absorber: used for ships, vehicles and other power machinery.

4) Yu type cylindrical shock absorber: used for ship main engine, auxiliary engine and other equipment.

5) SH type double plate shock absorber: used for marine machinery and equipment.

6) Z-type rubber equal frequency shock absorber: widely used in various machinery, instruments, machine tools, equipment, etc.

7) Jpz type three-way equal stiffness shock absorber: mainly used for aerospace and instrumentation.

8) “31 ‘type rubber shock absorber: used for ship main engine and electronic scale.

9) WJ rubber shock absorber: it is widely used and can bear loads in any direction.

10) JP rubber shock absorber: suitable for electronic instruments and meters to protect the whole machine from vibration and impact.

11) 6wn diesel locomotive shock absorber: used for diesel engine main engine.

12) JG shear shock absorber: used for fans, air compressors, freezers, water pumps and precision instruments and meters.

13) Jpz type small shock absorber: used for various isolation and anti impact devices.

Main application fields of rubber shock absorber: rubber shock absorber for automobile; Rubber damping products for railway locomotives and railway sleeper pads; Rubber shock absorber for bridge; Rubber shock absorber for building engineering

Contact Qiguang Tech

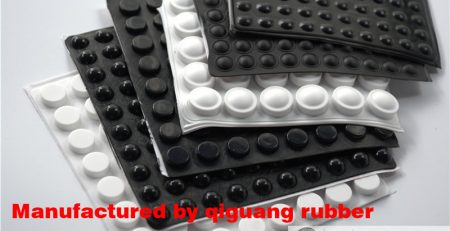

Qiguang Tech is a professional Rubber and Silicone parts development and manufacturing in Shenzhen, China

Focus on the development and manufacture of rubber silicone products more than 10 years.

Our advantage is Customize all kinds of rubber and silicone products

Mobile : 86-13669519751

Phone: 0086-755-84552919

Email: sara@qiguangtech.com

allen@qiguangtech.com