07

Jun

rubber stopper

Rubber cover

Rubber cap

Rubber sheath

Rubber sheath coil

rubber insert

Rubber shock absorber pad

rubber buffer

Rubber regulator

rubber sleeve

rubber band

Silicone rubber seal

Silicon rubber waterproof ring

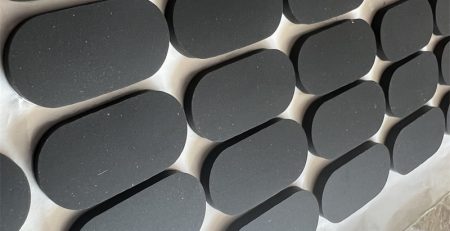

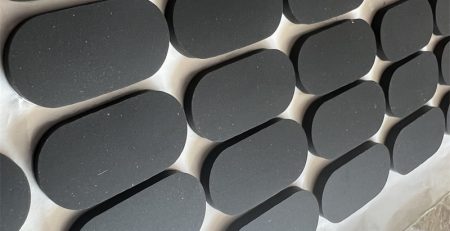

Rubber back glue foot pad

Rubber foot pad

rubber tube

Rubber dust cover

Rubber suction cup

Rubber suction ball

rubber pneumatic bag

Rubber groove

elastomer connector

Rubber O-ring

Silicone rubber grip, silicone rubber handle sleeve

Silicone…

read more

20

Oct

Silicone rubber products are made of methyl vinyl silicone rubber as based rubber, adding various fillers (reinforcing agent, heat resistance agent, modifying agent, etc.) by mixing, pass, filtration, sulfur, molding, extrusion, bonding and other production processes. Silicone rubber products are silicone rubber and rubber…

read more

08

Nov

Applications:The product in strong adhesive,safe and easy to use,easymove,shockproof,noise reduction,wear resistance,to prevent scratches between the things and the table or the floor surfaces,protect the floor and table,keep the furnitures for long life,Also can be used to make up the furniture,desk,cabinet,machines,electric appliance and so on…

read more

03

Mar

Silicone rubber (Silicome Rubber) is a new type of heat-resistant polymer elastic material. Silicone rubber is characterized by high temperature resistance, excellent cold resistance, the temperature range is-50 degrees+260degrees. Excellent aging resistance (ozone resistance, oxidation resistance, radiation resistance, light resistance, climate resistance). In free state,…

read more

18

May

The reason why the rubber shock absorber is so widely used is because it effectively uses the following characteristics of rubber:

1) Rubber has high elasticity and viscoelasticity;

2) Compared with the steel material, the elastic deformation of…

read more

17

Nov

Silicone rubber products are made of methyl vinyl silicone rubber as based rubber, adding various fillers (reinforcing agent, heat resistance agent, modifying agent, etc.) by mixing, pass, filtration, sulfur, molding, extrusion, bonding and other production processes. Silicone rubber products are the silica gel and…

read more

21

Jun

Applications:

rubber bushing or rubber sleeve is a class of rubber sealed products. Also known as dust cover, dust cover. Is the automobile and tractor front and rear wheel axle, transmission shaft and other parts for dust, oil spillover, construction machinery, substation and other industrial…

read more

30

May

How much is the price of rubber feet?

There are many factors that affect the price of a rubber feet, such as size, quantity, delivery date, and whether it needs to be Cutomized or not.

Qiguang tech has more than 10 years experience in customizing…

read more

18

Oct

Do you know why the customized rubber products are not lack of material and smooth surface?

Customized rubber products look beautiful and the key to accurate size is the mold, if a rubber product mold opened perfectly, then made the product feel good.

QIGUANG RUBBER has…

read more

14

Jun

New Rubber Seal Qiguang rubber Promises Better Performance and Sustainability

rubber gasket

A team of researchers from the University of California, Berkeley, has developed a novel rubber seal that could enhance the reliability, durability, and eco-friendliness of various products and systems. The breakthrough material, called “nano-rubber,” is…

read more