In general,we use shore to sate the hardness of rubber or silicone products,such as shore A,shore C and Shore A,different material has different shore unit.

Now,i want to introduce as follows;

Shore—— refer to Shaw hardness or

Shaw hardness – Shore scleroscope hardness

HS. for short A standard representing the hardness of a material. By the British Shore (Albert F.Shore) first proposed.

The elastic rebound method is used to drop the pin from a certain height to the surface of the material under test. The pin is a small cone with a tip, often inlaid with diamond. The hardness is expressed by the measured height of the pin rebound.

Xiao’s hardness test is a kind of dynamic force test. Compared with the static force test methods such as cloth, Luo and Wei, the accuracy is slightly poor. Under the influence of the factors such as perpendicularity and surface finish, the data dispersion is large, and the comparison of the test results is limited to materials with the same elastic modulus. It has certain requirements for the thickness and weight of the sample and is not suitable for thinner and smaller samples, but it is a portable instrument, which is convenient for field testing, its structure is simple, easy to operate and the test efficiency is high.

The Shaw hardness meter is suitable for the determination of Shaw hardness of ferrous and nonferrous metals. Xiao’s hardness meter is easy to carry, especially suitable for large and medium-sized workpieces in metallurgical and heavy machinery industries, such as large components, castings, forgings, crankshaft, roll, super large gear, machine tool guide and other workpieces. In rubber, plastic industry is often called Shao hardness.

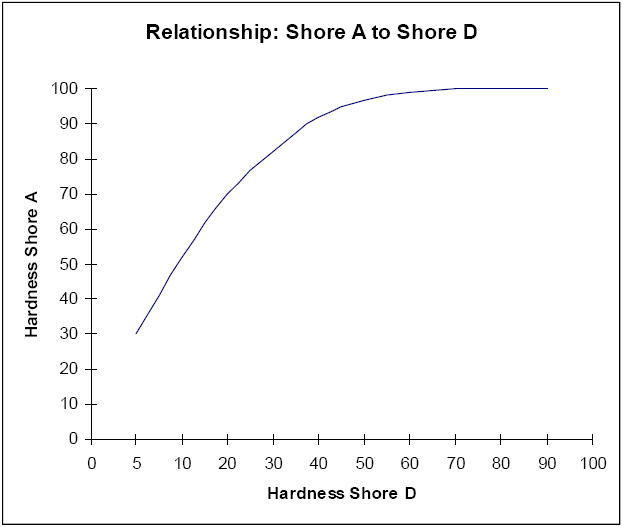

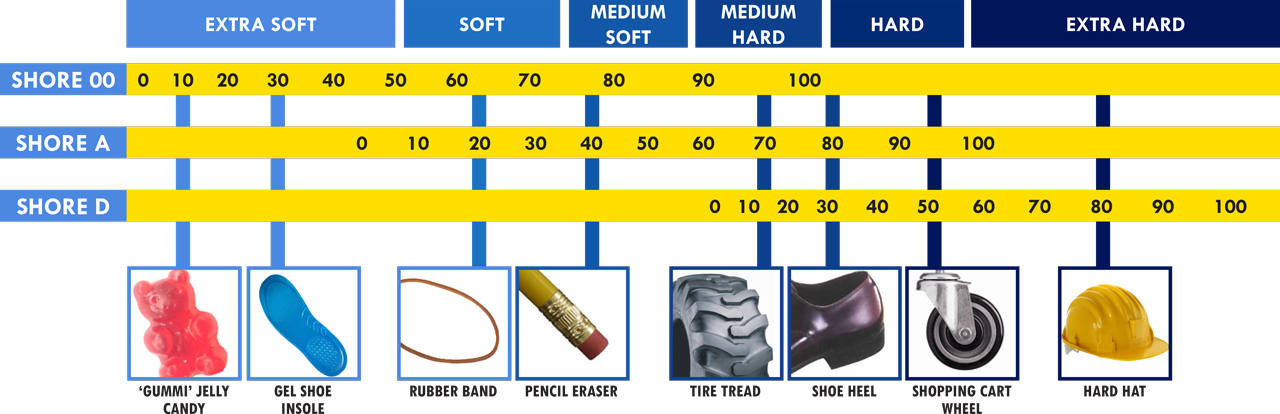

The principle of SHORE A and SHORE D is the same. Under the standard conditions, the standard pressing needle is pressed into the surface of the standard sample, and the depth of the indentation is investigated to measure the hardness of the sample. The difference is that the shape of the needle is different, the SHORE A is round, and the SHORE D is conical. so A used to test soft plastic, elastomer and rubber material, D used for hard plastic and high hardness elastomer with rubber material; only changed to D type when the measurement value of A is greater than 90, and use A type when the reading of the type is less than 20.

SHORE A 10-90, change SHORE OO when SHORE A <10

When SHORE A>90 change SHORE D

Shore A and Shoer 00 are two types of hardness meters, Shore A are testing rubber, Shoer 00 are testing low hardness foaming materials. There is no formula for changing numbers.