1. Why does the silicone rubber mold turn over less frequently.

Too much silicone oil is added in the process of making the mold, and the silicone oil destroys the molecular weight of the silica gel, so the mold will be less turning times and not durable. If you make small products with more complex pattern, use the silica gel with large hardness to open the mold, there will be the phenomenon of less mold times, because the silica gel will be very brittle and easy to break. On the contrary, if the build product is made with less hardness silicone to make the mold, the result will also be unsatisfactory. Because the silicone is too soft, its pull and tear strength will be reduced, and the mold will deform, so the number of mold turns will be reduced. The mold silicone itself is very good, silicone is not good or bad, only suitable and not suitable. To use the suitable product hardness size of the silicon gel to make the mold will not produce this situation.

2. Why the silicone rubber mold is burned.

Because unsaturated resin and resin products with peroxide curing agent, the resin reaction will produce a lot of heat, the general resin curing time for 3 minutes, so 3 minutes as soon as possible to mold, to prevent the silicone mold will not produce the phenomenon of mold burning.

3. Why the mold silicone rubber will appear in the surface dry phenomenon.

Mold silica gel is belongs to the condensation type of silica gel, it is determined by absorbing the water in the air and curing, silica gel in the process of making, the water steamed dry, and without the right amount of water, there will be a dry phenomenon in the surface. Solution: this phenomenon does not belong to the product quality problem, but because there is no control of water, improve the storage period of silicone, shelf life is long will appear some phenomenon, as long as the use of silicone, the appropriate amount of 0.05% water, stir evenly can solve some conditions.

4. Why the mold silicone rubber will appear poor tensile force phenomenon.

Because in the customer in the process of making mold, in order to reduce the viscosity of silicone, silicone easy to operate and added in the silicone a lot of silicone oil, this will make the silicone become very soft, produce tensile, tear strength is reduced, the phenomenon of tensile variation, resulting in the mold is not durable, short service life, die less phenomenon.

5. Why the mold silicone rubber will appear oil leakage condition.

The mold silicone itself will not emit oil, the oil is because of the addition of compound silicone oil (silicone oil and white ore oil) in the operation process, because white ore oil is a petrochemical product, not silicone oil.

6. Why the mold will produce acid and alkali resistance, aging resistance phenomenon.

In the process of making silicone mold, it is recommended that customers should not add any silicone oil, if necessary, the amount of silicone oil should not exceed 5%~10%. Because the excessive addition of silicone oil will destroy the molecular weight of silica gel, so the mold will produce the phenomenon of inresistance to acid and alkali, and aging.

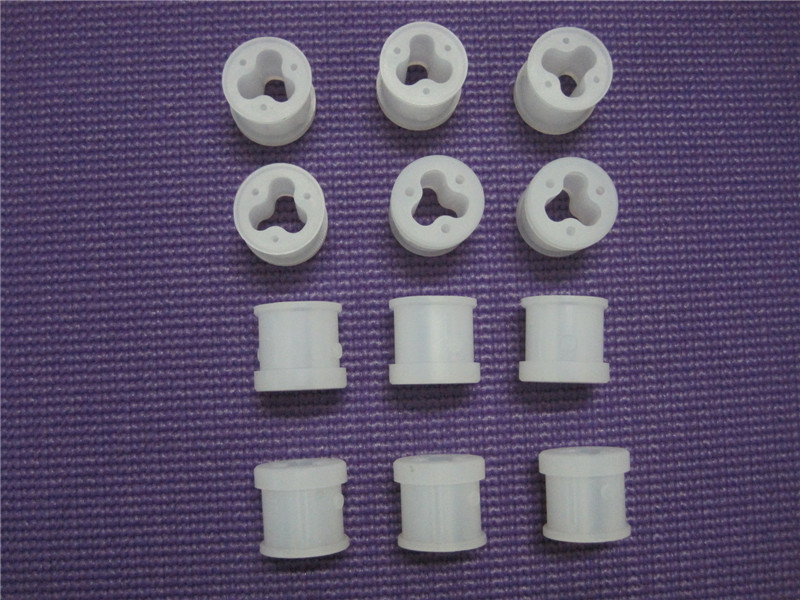

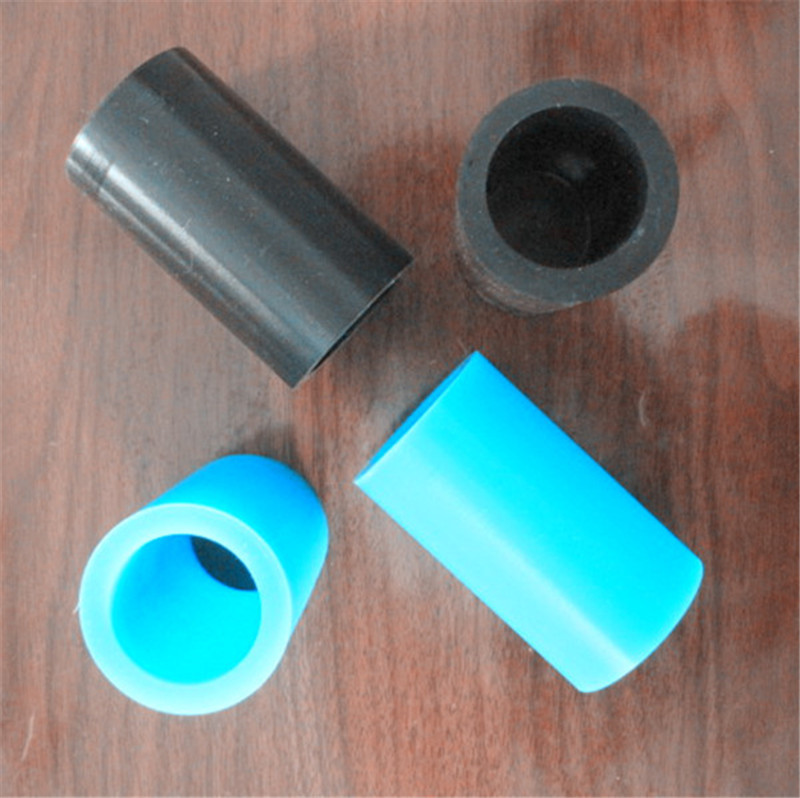

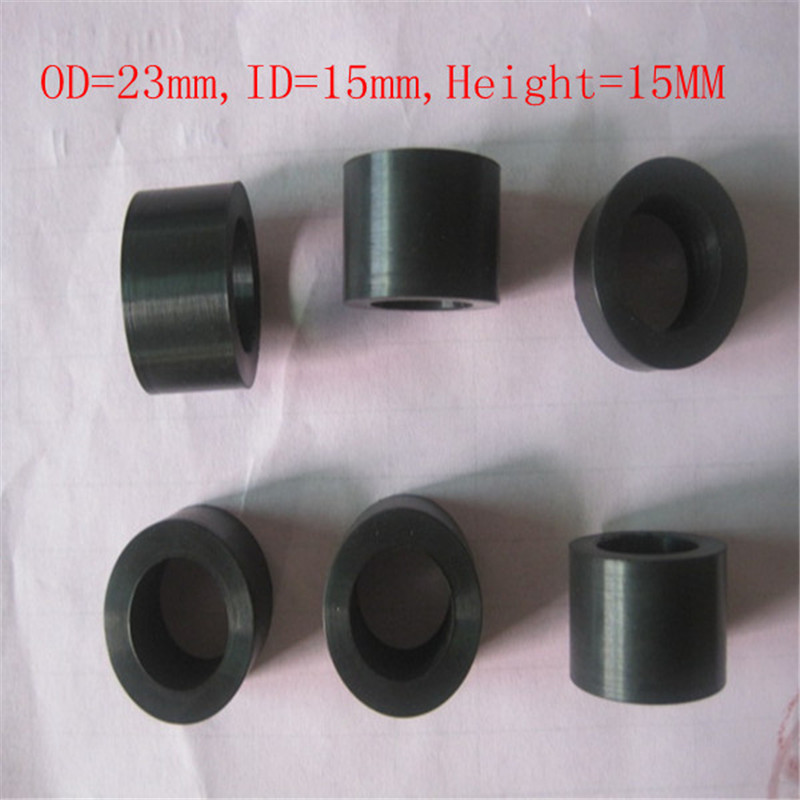

Product industry application editing

silicone bushing,silicone bellows,silicone sleeve